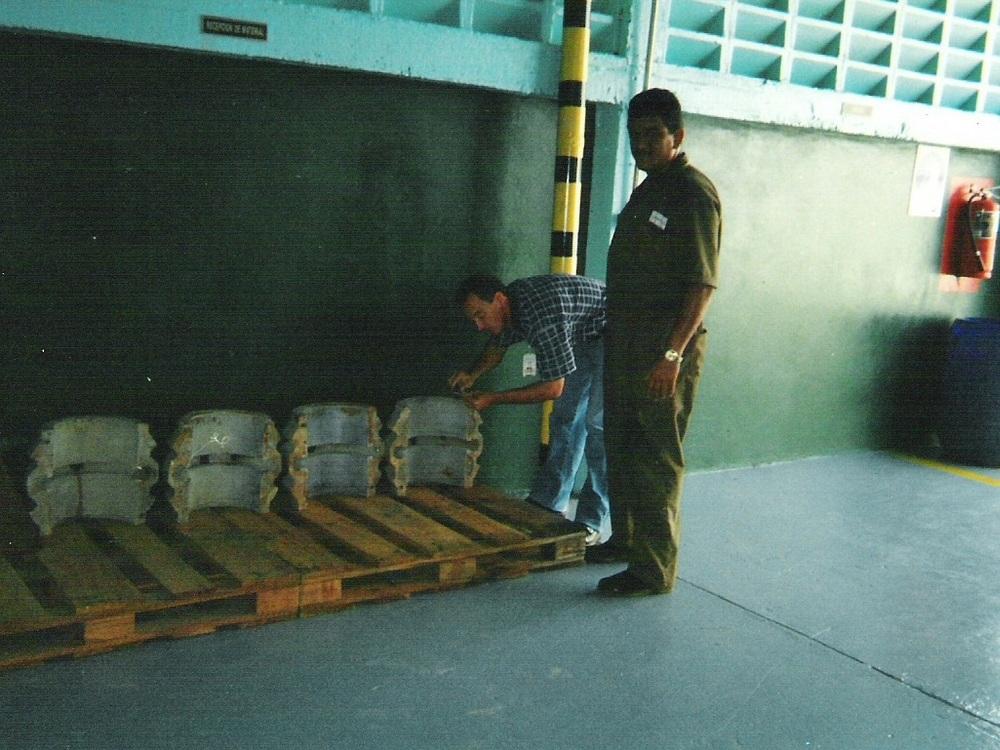

Manufacturing and Assembly

There is complexity in the manufacturing of the parts and elements we work with. This complexity, significantly hinder the assembly of constructions and structures.

Our team of professionals, technicians and craftsmen is prepared to carry out the tasks efficiently and safely, reducing the time used in these activities.

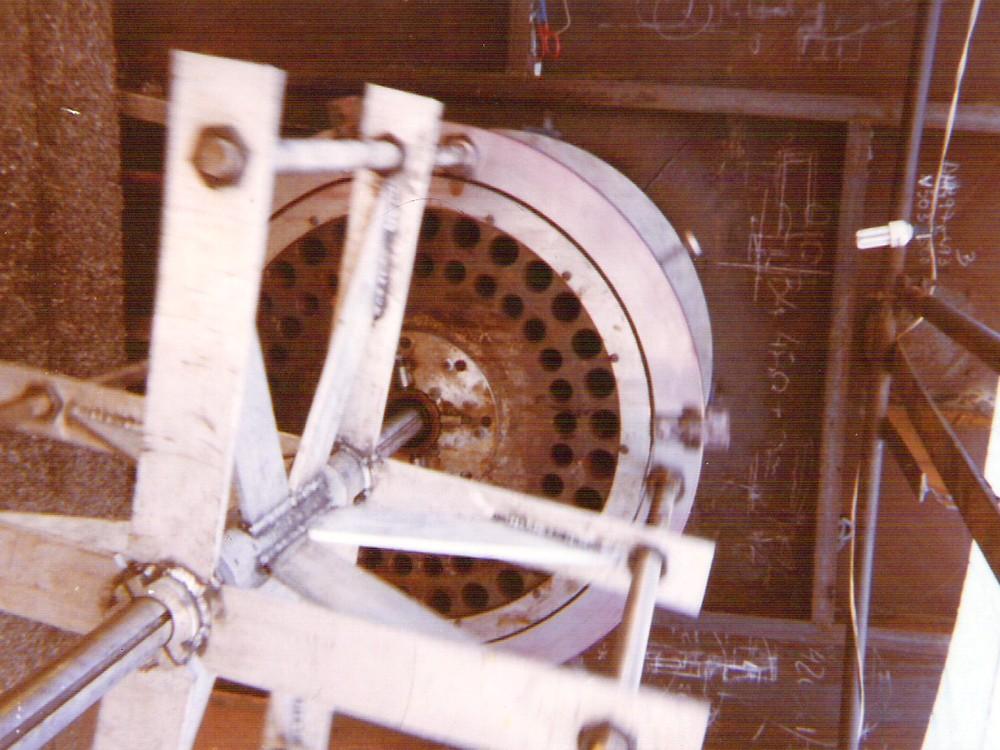

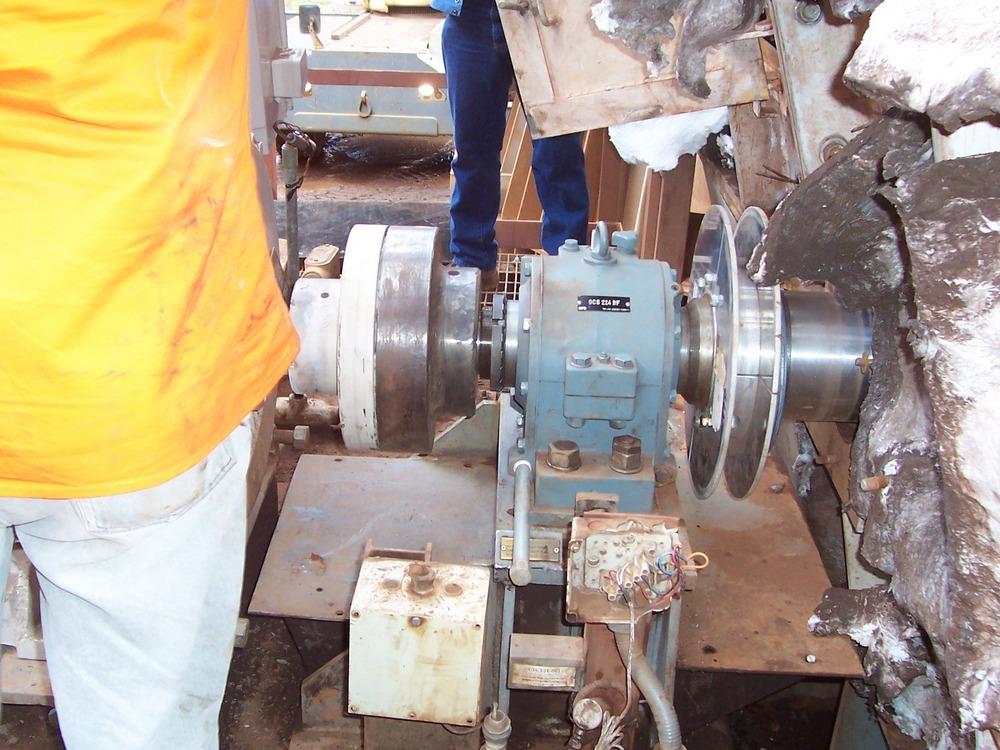

On-site Machining

Moving repair equipment can present some challenges in regards to size, weight, geometry, or time frame.

Master Tech has an engineering department that through work assessment, design and manufacturing of reliable devices, together with portable equipment of high technology machining site, ensures the final dimensions and finishes.

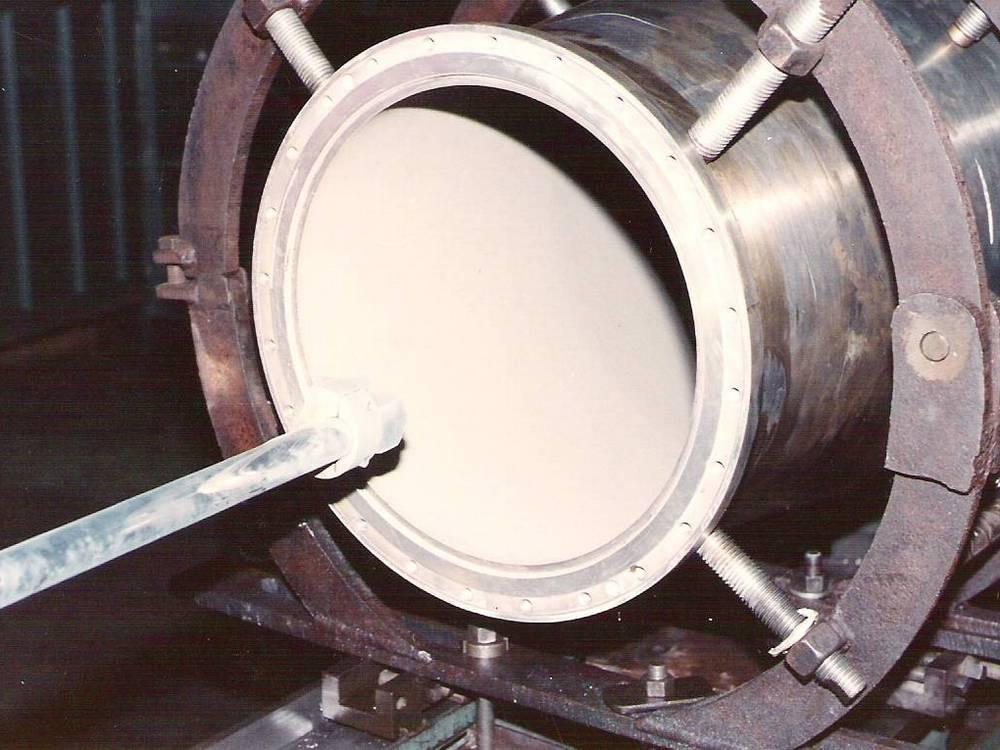

Workshop Repair & Machining

We use metal-mechanical equipment that allows us to manufacture tailored parts regardless of size, shape or material.

We work with Shielded Metal Arc Welding (SMAW), Gas Metal Arc Welding (GMAW/MIG), Flux Cored Arc Welding (FCAW) and Gas Tungsten Arc Gas Welding (GTAW/TIG) Welding Processes.

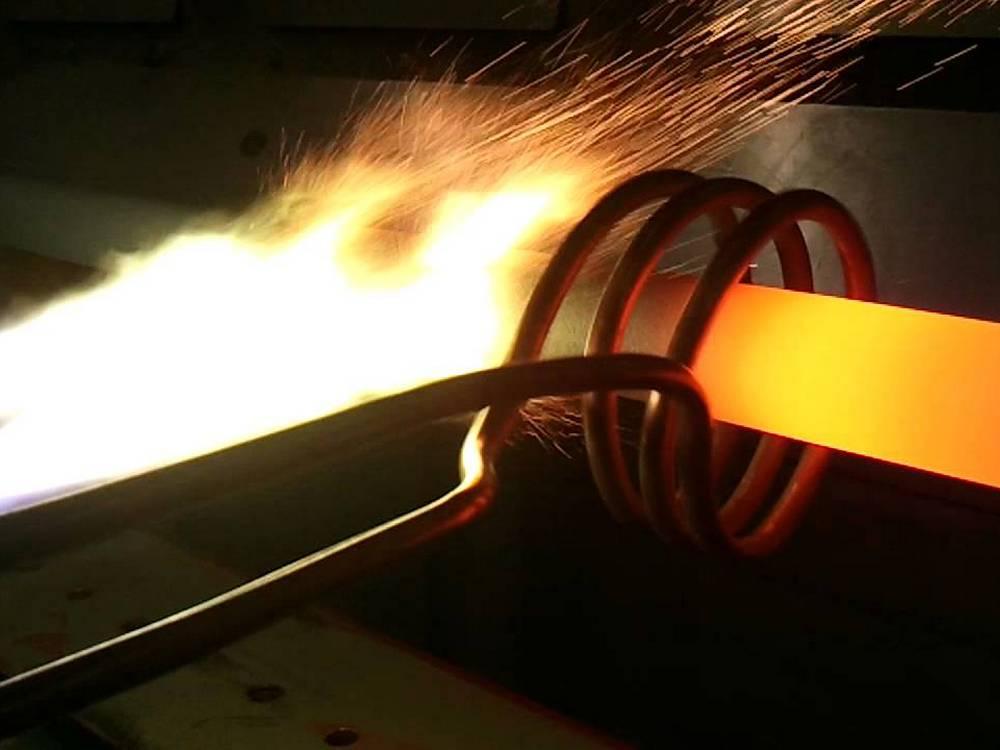

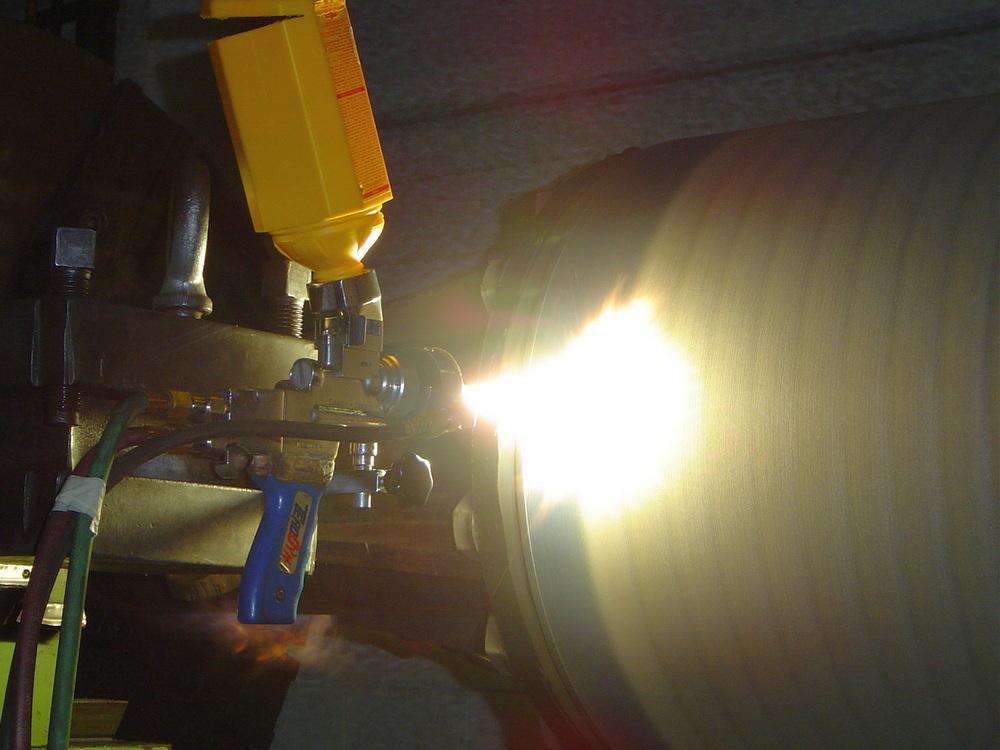

Thermal Spray

We perform this type of process in which finely divided particles of metallic or non-metallic coating materials are deposited in a semi-fused state on a substrate.

There are several sub-processes of this type that are metallized, fused, HVOF, and Plasma.

The materials contributed in the form of powder, wire or rod, can be metallic, non-metallic, ceramic and plastic.

Rotating Equipment

We have the experience and cutting-edge equipment necessary to meet the goal of early diagnosing future failures, using vibration analysis technique to detect damage and malfunction of equipment at production sources.

We can attend the following industries:

1. Energy Sector

Electric generators.

Steam turbines

Gas Turbines

2 Industrial Sector

Electric motors

Gearboxes

Compressors

Pumps

Forced throws

3. Oil and Gas Sector

Turbochargers

Powerful pumps

Turbogenerators

NDT Inspections

This type of inspection provides us with information about the materials that make up the equipment and structures. We can carry out the following procedures:

VT – Visual Inspection,

PT – Penetrating Liquids

MT – Magnetic Particles

ET – Electromagnetism

UT – Industrial Ultrasound